1,3-Dibromopropane: More Than Just a Building Block in Chemistry

Historical Development

I look back at the early years of organic chemistry, and I see the roots of 1,3-dibromopropane stretching back through the era of foundational halogenation methods. Chemists searching for reliable haloalkanes stumbled upon such compounds while charting the reactivity of bromine with various hydrocarbons. The discovery of 1,3-dibromopropane wasn't exactly headline news in those days, but its arrival opened several doors for organic synthesis, especially as researchers grew fond of exploring carbon–bromine linkages for constructing more complex molecules. As industrial organic synthesis took shape through the 20th century, this particular dibromide found a seat on the bench as a tool for creating functionalized intermediates and cyclic compounds. What started in the glassware of early laboratories worked its way into industrial pipelines, especially as polymer science hit its stride and the need for versatile three-carbon units increased.

Product Overview

The world knows 1,3-dibromopropane as a modestly sized, dense organic liquid, clear to faintly yellow, with a straightforward formula: C3H6Br2. It rarely demands attention on its own, yet anyone who’s figured out how to stitch carbon chains knows this molecule can be a workhorse. Loaded with two reactive bromine atoms at either end, its appeal lies in the ease of conversion. You pick up a bottle of it today, you’re likely looking for a way to make a ring, link molecules together, or swap those bromides for other functional groups on a lively carbon skeleton. Its shelf life stays long if you store it cool and dry, shielded from light. Companies selling 1,3-dibromopropane know users want a substance free of water and acids, since impurities can turn even a simple reaction on its head.

Physical & Chemical Properties

Pouring 1,3-dibromopropane, you’ll notice right away it weighs heavier than your usual solvents—its density hovers around 2.17 g/cm³. Its boiling point sits at a confident 196–200°C, which means you can use regular glassware without worrying about runaway vapor. With a melting point well below freezing, it stays liquid in any ordinary lab setting. The molecule resists water (insoluble) but dissolves easily in organic solvents. What stands out for chemists is the balanced reactivity of the carbon–bromine bonds: strong enough to survive regular handling, but reactive enough to invite a range of nucleophilic attacks. If you’re aiming for substitution, elimination, or cyclization, this compound rarely disappoints.

Technical Specifications & Labeling

Suppliers don’t take shortcuts with 1,3-dibromopropane labeling. Each bottle lists batch purity, water content, and—increasingly—trace halogenated impurities. These metrics matter. Not every reaction calls for ultra-high grade, but slipshod quality or incomplete labeling burns time and resources. I always check for UN numbers and GHS hazard symbols. For transport, it counts as a hazardous material, so you’ll spot the correct warning and packaging codes. Lot numbers and origin details guarantee traceability, ever more important now with tighter regulations. Many labs lean on 98% or higher purity, with GC or NMR reports available to compare side by side with previous or alternate batches.

Preparation Method

Classic syntheses of 1,3-dibromopropane usually start with 1,3-propanediol or with propylene. You take 1,3-propanediol, react it with phosphorus tribromide (PBr3) or hydrobromic acid, and you watch both hydroxyl groups swap for bromines, clean and quick, though keeping water out through the process is critical. Some routes begin with allyl bromide or propylene, using selective bromination techniques to add the second bromine atom at the right position. Industrial plants often prefer continuous processes and sealed reactors to avoid side-reactions and to mop up any volatile by-products. The most successful preparations control water, temperature, and stoichiometry tightly, relying on distillation and careful scrubbing to yield the pure product.

Chemical Reactions & Modifications

In my own experience, I’ve reached for 1,3-dibromopropane countless times to make cyclic compounds, from small heterocycles to macrocycles for ion transport. Add a bit of sodium or potassium salt, the molecule folds in on itself, and you’ve made a thiacyclopentane or a crown ether precursor. It works as a bifunctional electrophile: each bromine can leave, replaced by nucleophiles such as amines, thiols, or alkoxides. When you want crosslinked polymers, this dibromide serves as a ready linker. Any good organic chemist knows how useful this arrangement is for controlled stepwise assembly. Alkylation, cyclization, Grignard formation, and even reduction to 1,3-propanedithiol—1,3-dibromopropane doesn’t shy away from any of it.

Synonyms & Product Names

You won’t always see “1,3-dibromopropane” on the label. Some suppliers call it trimethylene dibromide, propyl dibromide, or 1,3-propylene dibromide. It also pops up in literature as sym-dibromopropane or 1,3-DBP. Knowing all possible synonyms saves headaches when you chase down references or source globally, since regulatory and shipping names sometimes switch things up.

Safety & Operational Standards

Safety matters, not just because regulations grow tighter every year, but because anyone spending hours in the lab deserves honest risk assessment. 1,3-dibromopropane comes classified as a hazardous, potentially mutagenic chemical, meaning gloves, goggles, and solid fume extraction stay non-negotiable. Skin absorbs it more easily than you think, so any spill means quick cleanup and proper disposal. Volatility stays low, but respiratory exposure can’t be dismissed. Many jurisdictions require annual review of handling protocols, spill kits close at hand, and clear labeling. Data sheets (SDS) stress regular training, and I’ve seen more institutions demanding safety documentation with every delivered batch, not just in the fine print.

Application Area

Chemists put 1,3-dibromopropane to work mostly as a synthetic intermediary. I’ve seen it in the development of new pharmaceutical scaffolds, as a starting point for sulfur- or nitrogen-containing rings, and in the preparation of ionic liquids. The plastics industry values it for crafting specialty crosslinked resins, because its bifunctionality neatly stitches together disparate polymer chains. In environmental chemistry, it shows up as a probe for degradation mechanisms of halogenated organics. The search for new ligands and macrocycles often brings researchers back to this dibromide, giving them a simple route to the right-sized carbon frameworks.

Research & Development

R&D arms have not lost interest in 1,3-dibromopropane, even after decades of use. Current trends explore greener synthesis methods, hoping to sidestep hazardous bromine handling through electrochemical or bio-catalyzed approaches. Research groups also test whether alternative leaving groups can mimic the classic reactivity with less toxicity. Solid-phase synthesis and polymer engineering push for functionalized derivatives, designed to speed up purification and reduce environmental risk. In materials science, 1,3-dibromopropane forms the backbone of novel cyclic architectures for molecular recognition and sensing.

Toxicity Research

We know 1,3-dibromopropane brings risks. Early toxicological studies flagged its mutagenic and suspected carcinogenic properties, especially on long-term or repeated exposure. Rodent models show clear organ toxicity, supporting the strict handling rules laid out in modern SDS paperwork. Chronic exposure data remains patchy, but evidence suggests limited but real risks to workers in large-scale production settings, especially when engineering controls fall short. Researchers have probed aquatic toxicity as well, given the persistence of brominated organics in wastewater—a reminder that environmental stewardship keeps pace with industrial scale-up.

Future Prospects

Looking down the road, I see regulations tightening, with demand for safer alternatives driving not just compliance, but innovation. Green chemistry trends favor catalytic and solvent-free methods, aiming to make compounds like 1,3-dibromopropane with less waste and safer by-products. There's room for more robust monitoring of workplace exposure and a stronger culture of safety, especially in emerging markets. Materials science and medicinal chemistry likely continue to draw on this dibromide’s versatility, even as new ligation and cyclization agents come online. Ongoing development of biodegradable analogs and smarter containment solutions shows there’s no standing still in the world of fine chemicals—adaptation and responsibility shape the future as much as curiosity ever did.

Understanding the Practical Uses of 1,3-Dibromopropane

1,3-Dibromopropane doesn’t often show up in headlines, yet it plays a role in research labs and chemical plants around the world. Its chemical structure might make it sound like a niche compound, but people use it for real purposes. You’ll often come across this clear, somewhat oily liquid as a building block for other molecules. It’s what chemists call an “alkylating agent.” That means it helps put two pieces of another molecule together, something like a molecular matchmaker.

Why Chemists Pay Attention

A lot of what I’ve seen in university labs comes down to making connections. 1,3-Dibromopropane gives chemists a way to link carbon atoms. If you crack open an organic synthesis textbook, you’ll find that it works as a bridge for smaller molecular fragments. Research teams use it to create various rings and chains that form the backbones of plastics, pharmaceuticals, and complex natural products. Pharmaceutical developers don’t use it to make the final pill or syrup, but they rely on it for early steps that eventually bring useful medicines to market. That step escapes most people’s attention, yet it means the compound directly affects what ends up on pharmacy shelves.

The Industrial Picture and Its Challenges

Chemical plants value efficiency. 1,3-Dibromopropane’s two bromine atoms make it a quick choice for pulling off double reactions, replacing other groups in a molecule, or sewing together different molecular threads. This trait pops up everywhere from the design of specialized plastics to advanced coatings and resins. Industries that push for lighter cars or stronger construction gear often turn to chemists who know how to bring these kinds of specialty chemicals into play.

Pictures of factory chimneys often stir up concerns about safety and pollution, and for good reason. 1,3-Dibromopropane is no friend to bare skin or lungs. Breathing vapors or touching the liquid can irritate or even burn, so the gear has to go on before the bottle comes out. Incidents in production yards underline how easy it is for things to go sideways if people skip the basics. Strong rules and regular training keep employees safe, yet some small businesses and schools can lag. I remember stories from colleagues just starting out, who got careless and learned hard lessons about chemical safety.

Environmental and Regulatory Concerns

Many brominated chemicals last a long time in the environment and can cause harm if used carelessly. Regulators in the US and Europe watch 1,3-Dibromopropane closely, setting strict exposure limits for workers and laying out tough waste disposal steps. Getting rid of old stock involves special hazardous waste processing, not just dropping bottles in the trash. Failures in handling or accidental releases can lead to soil and water problems. Every step from delivery to storage and cleanup needs extra scrutiny.

Better Solutions and a Safer Future

Chemists don’t ignore risk. Industry groups and government agencies highlight best practices like closed reactor systems, better ventilation, and continuous worker training. Newer green chemistry approaches aim to sidestep dangerous halogenated compounds altogether, using safer replacements when possible. Academic journals now share breakthroughs in alternatives or procedures that shrink environmental footprints. The industry doesn’t drop old chemicals instantly, but pressure from consumers, regulators, and investors drives adoption of safer practices. Everyone benefits when safety, health, and innovation move together.

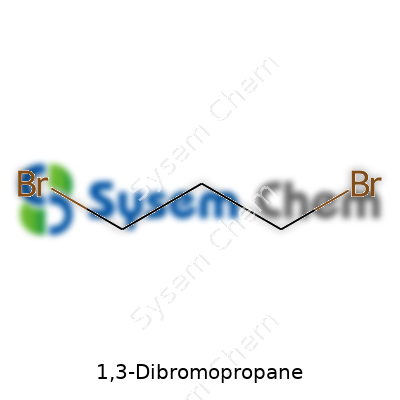

Understanding What 1,3-Dibromopropane Is

In the world of chemistry, I’ve found that getting comfortable with the names often leads to understanding the guts of the molecule. 1,3-Dibromopropane comes up during basic organic chemistry, the kind of lesson that sticks with you long after you’ve left the classroom. Let’s break that name down. The “propane” part signals three carbon atoms joined in a chain. The “1,3-dibromo” prefix means there’s a bromine atom attached to the first and third carbons. If you picture propane as C3H8, every time you add a bromine, you swap it for a hydrogen.

Putting the Formula Together

The molecular formula asks a direct question: how many atoms stand in the molecule, and what are they? With 1,3-dibromopropane, two hydrogens fall off when the two bromine atoms join the chain. That gives you C3H6Br2 — three carbons, six hydrogens, two bromines. This formula describes everything about the molecule’s backbone and its slightly menacing strength; the two halogen atoms pull on the chain, changing the way it interacts with other chemicals.

Application in Research and Industry

Years ago, in a makeshift lab meant mostly for undergraduates, I spilled a bit of 1,3-dibromopropane by mistake. You learn the value of good gloves in those moments. Besides the sting to my pride, the experience showed me why chemists treat this compound with respect. Used as an alkylating agent, it introduces three-carbon units into bigger, more exotic molecules. Its reactivity creates options in synthesis routes for pharmaceuticals, pesticides, and materials, which fuels the demand for accuracy in its formula and structure.

Safety Matters

The bromine atoms in this molecule aren’t just passengers — they affect how the whole thing behaves. Halogenated compounds carry long-term health implications. Studies document how exposure can irritate skin, eyes, and lungs, and potentially lead to more severe outcomes with repeated mishandling. The molecular formula isn't just a string of letters and numbers; it points to potential risks and chemicals that require safe storage and disposal processes. Failing to treat it with respect invites problems for workers, the environment, and the community near a chemical plant.

The focus shifts to responsible use and equipment that can handle energetic and unpredictable organic molecules. Choosing the right glove material, using fume hoods, and following disposal guidelines make science possible without a trail of issues. Firms must prioritize detailed safety data sheets and staff training. This isn’t overkill; it’s the bare minimum for anyone handling reactive organic halides.

Building Knowledge and Reducing Risks

Every time educators discuss compounds like 1,3-dibromopropane, they set the stage for safer work and smarter solutions in research. There’s a growing push for green chemistry, seeking out alternatives to hazardous brominated organics when possible. Even though a simple formula like C3H6Br2 seems straightforward, understanding why each atom sits exactly where it does, and what the whole molecule could do, brings insight that can’t be ignored. It’s the first step toward developing safer chemicals and processes that don’t compromise on function but keep people and the planet at the center.

The Real Dangers Lurking in the Bottle

Most folks in the lab remember the first time they handled a halogenated hydrocarbon. It smells strong, stings the nose, and clings to your gloves even after you wash up. 1,3-Dibromopropane brings hazards you can’t wave away. It irritates skin, eyes, and lungs. High exposure can affect your nervous system. Some studies link brominated chemicals to cancer risks.

The first time I spilled a little on my glove, I caught a whiff and respect for the stuff kicked in fast. Your hands feel warm, your eyes might water, and you realize half a second separates routine handling from a scary moment.

Thinking Twice Before Grabbing the Bottle

Ventilation makes all the difference. Fume hoods pull vapors away, saving your lungs and anyone nearby. I once skipped the hood for a “quick transfer,” then ended up coughing for hours. Never again.

Gloves matter. Not every glove blocks organics. Nitrile or butyl stands strong, but thin latex barely slows some solvents down. Double up if you must. Eye protection isn’t just eyewash for safety paperwork. 1,3-Dibromopropane doesn’t care if you blink—it’s unforgiving to the eyes. Goggles with side guards shield the mucous membranes and cut the risk.

Long sleeves and lab coats are more than a uniform. Brominated liquids can soak shirts, and quick action counts for nothing if a spill touches skin. Some wear disposable aprons for bigger pours. I’ve never regretted over-preparing for a substance that can cause blisters.

Handling Spills and Waste Without Drama

If you tip over a container, the biggest mistake is panicking. Don’t try to wipe it up with bare hands. Absorb the spill with specialized pads—pipecleaners, towels, or sand can sometimes work, but chemical spill kits make cleanup safer. Then, collect everything for hazardous waste disposal. Never pour this compound down the drain or into trash cans.

Every lab should have a clear path to the eyewash and shower. I learned this lesson the hard way when a bench partner lost seconds searching for the eye station during a splash incident. Nobody gets time back in a crisis. Know the route before you need it.

Storing for Tomorrow, Not Just Today

Lock the bottle away in flammable safety cabinets, far from heat sources or sunlight. Hydrocarbons like this want to creep and evaporate, even when the lid looks tight. Label containers every time because hours-old memory fades, and misidentified bottles cause accidents.

Keep an up-to-date inventory of what you have and make sure everyone in the lab knows where to find the Material Safety Data Sheet. It’s not just busywork. MSDS sheets spell out what symptoms to watch for, how to treat accidental exposure, and how to clean up.

Solutions That Stick—Training, Routine, and Attitude

Safety isn’t about rules on the wall—it’s about habits. Regular training refreshes muscle memory. Mock drills remove guesswork in real emergencies. Experienced workers model best practices for new hires. No one gets a pass for sloppiness, because inexperience and overconfidence invite mistakes with chemicals like 1,3-Dibromopropane.

Simple precautions save nerves, money, and sometimes, lives. Gloves, goggles, good ventilation, and a plan for spills create confidence to focus on experiments, not what might go wrong.

Every time I see a colleague treat these steps as obstacles, I remember the stories from emergency rooms. The price of safety gear never compares to the cost of a split second’s neglect.

A Closer Look at 1,3-Dibromopropane

1,3-Dibromopropane doesn’t pop up in many headlines, but those working with chemicals know every detail matters. This liquid, clear with a sweetish odor, has a simple but impactful formula. Some folks use it for organic synthesis and research labs, but danger lurks if it gets loose. Talking about storage isn’t just a box to check — it can mean the line between a safe day at work or a frantic emergency call.

Health Risks and Experience on the Floor

Direct contact with 1,3-dibromopropane can hurt. It irritates skin and eyes. Fumes can attack lungs, leaving someone coughing or worse. In my college lab days, ventilation failures quickly turned routine experiments into hazards. I remember the scramble when a seal broke: sharp, unpleasant vapors flooded out. Eyes started stinging in seconds — proof enough that no bottle of the stuff belongs next to a desk or where people eat their lunch.

Storage That Keeps People Safe

Too many accidents start with sloppy practices. There's no substitute for a tight cap, a proper label, and a locked cabinet. I always pick cabinets made for flammables or corrosives. They're built with metal, resist acid, and often feature special vents. Anything corrosive or toxic, like 1,3-dibromopropane, deserves nothing less. At my first job, an experienced tech told me, “If it can spill, it will. Stop it before it does.” Simple, but wise.

Any area filled with 1,3-dibromopropane needs solid ventilation. One whiff is enough to send folks running for fresh air. Good air flow keeps fumes away from workspaces. At bigger operations, exhaust hoods and air monitors always stay on. Even storing a few bottles, I look for low-traffic storage rooms far away from food, water, and heating systems.

Spotting Hazardous Combinations

Storing chemicals close together tempts fate. Strong acids, bases, or oxidizers can react badly with brominated compounds like this one. I keep a clear log of every bottle, with each item in its own section, never mixed with unknown containers. Staff should get regular safety briefings, not just a dusty binder on a shelf.

Environmental Responsibility and Regulations

Leaking or spilled 1,3-dibromopropane drifts straight into groundwater or soil. The EPA doesn’t take such mistakes lightly, with enforceable limits for hazardous pollutants. In my city, fire inspectors drop by without warning. They’ll write up just one leaky cap or missing spill tray. Drains and sinks are off-limits — only certified chemical waste handlers touch this stuff.

Insurance audits share the same attitude. They check for secondary containment trays to catch drips. Double containment keeps families and neighborhoods safe: nobody enjoys reading about a toxic plume next door.

What Works: Practical Safety Steps

Gloves, goggles, and lab coats aren’t just for looks. The right gloves — usually nitrile or neoprene — hold up against spills. Labels stay clear and visible, with emergency contacts just in case. I keep spill kits ready, stocked with absorbents, neutralizers, and detailed instructions for fast clean up.

Training goes beyond paperwork. Anyone handling 1,3-dibromopropane watches real-life drills. Practice shows where mistakes creep in, whether that's topping off a bottle or stacking containers too high. In my experience, a safety culture grows best with open communication and clear routines.

Getting to Know 1,3-Dibromopropane

1,3-Dibromopropane isn’t something most folks run into every day, but it pops up in chemistry labs all over the world. It’s a liquid, clear as water, with a smell a bit sharper, used mostly in organic synthesis. Folks working in research or industry turn to it whenever a three-carbon dibromo chain is needed. Over my years working in a university chemistry lab, I’ve watched this compound change hands, usually after repeating the same safety lecture — “know what you’re handling.”

The Facts: Boiling Point

When measuring out chemicals, knowing the boiling point is as basic as wearing gloves. 1,3-Dibromopropane has a boiling point close to 196°C (385°F). That’s hotter than the water in your kettle, way beyond safe kitchen work, and even outside the comfort zone of most lab heating plates. It matters because reaching that temperature means more than just steam. Vapors can sneak out of flasks, threaten air quality, and remind you in an instant why proper ventilation isn’t optional. I remember a time someone in our lab didn’t check the temperature setting, things got smoky real quick, and everyone ran to open the windows.

Why Boiling Point Changes the Game

Boiling points control how chemists separate, mix, and handle substances. At 196°C, 1,3-dibromopropane shows it’s more stubborn than simple solvents like acetone or alcohol. Distilling it takes some muscle, so to speak, and demands more energy from burners or heating mantles. That means extra costs in energy bills if you’re running big batches in a factory. It also means watching out for fire hazards. High-temp compounds like this put lab equipment to the test. In my experience, flasks need thicker glass, and clamps must grip tighter. Once, a colleague tried using a cheap flask for something just as hot, and the glass cracked under the stress. A close call, and a few scared faces to remember.

Risks and Safety: Beyond the Number

Take a liquid this volatile up to its boiling point, and fumes become a real risk. 1,3-Dibromopropane isn’t just a harmless vapor; it can irritate skin, eyes, and lungs. Nobody wants a headache, let alone something worse, just from doing their job. Proper fume hoods, clear eyewash stations, and well-drilled safety routines save a lot of trouble. In labs where corners sometimes get cut to save time, strict discipline kept us out of the ER more than once. I’ve learned to never underestimate the sting of brominated vapors. Even a quick splash on the arm burns more than you’d expect.

Looking for Solutions

Clear labeling and solid training turn a risky chemical into an everyday tool. Keeping the temperature controls honest, running extra ventilation, and choosing the right containers make all the difference. If manufacturers review their heating routines and check equipment more often, they’ll see fewer accidents. Regular audits help, too. Teaching everyone to respect the numbers on a safety data sheet, from new hires to seasoned techs, goes a long way.

Bringing Experience to the Table

After years of working with all sorts of chemicals, nothing beats old-fashioned know-how — double-checking equipment, asking questions, and knowing you can’t trust your nose alone. 1,3-Dibromopropane’s boiling point tells more than just a temperature; it points to a need for caution, preparation, and teamwork.