Acetyl Bromide: A Practical Look from Lab to Industry

Historical Development

Back in the nineteenth century, chemists took their first steps with acetyl bromide. Their curiosity about acyl halides led to experiments with everything from harsh acids to basic glassware, resulting in a landscape where reagents could form new carbon–heteroatom bonds. Early studies didn’t just scratch the surface; they set the foundation for how chemists approached both the synthesis and handling of volatile chemicals. The understanding of acetyl bromide grew as researchers realized its aggressive acylating power could open doors in organic synthesis. Working through glassware concerns and reagent purity, those early chemists mapped paths for today’s tighter safety standards and reliable supply chains in laboratories around the world.

Product Overview

Acetyl bromide stands out for its sharp odor and colorless, fuming liquid nature. Chemists prize its ability to introduce acetyl groups into all sorts of molecules. It’s a reliable workhorse where acetic acid derivatives are in demand. Typically, manufacturers ship it in tightly sealed, corrosion-resistant containers since exposure to air or moisture can turn the compound into a corrosive acid mist, threatening both health and product utility. Storage needs do not bend. Anyone handling it learns quickly: keep the reagent away from water, and always use it in well-ventilated fume hoods. The chemical’s simplicity on a molecular level belies the rippling impact it has across academic and industrial chemistry.

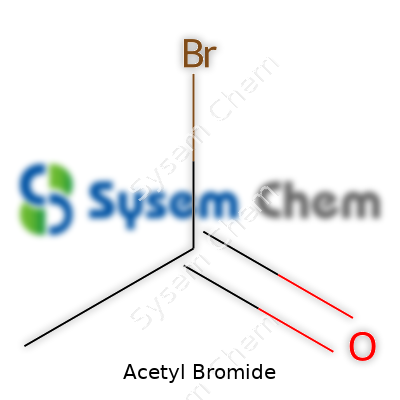

Physical & Chemical Properties

This liquid weighs in with a boiling point around 76°C, standing lower than acetic acid chloride and making it more volatile—a property requiring care during transfer and reaction set-up. It comes in at a density of 1.65 g/cm³, and its molecular structure, CH3COBr, displays the classic hallmarks of an acyl halide. Sharp, acrid fumes can overwhelm even brief openings of a bottle. Acetyl bromide reacts violently with water or alcohol, quickly morphing into hydrobromic and acetic acids. Such reactivity calls for both skill and respect in handling. Even slight contamination with water can ruin a reaction or endanger users.

Technical Specifications & Labeling

Suppliers provide acetyl bromide as a high-purity material, often above 97%. Labels bear the CAS number 506-96-7, hazard symbols for corrosive and toxic agents, and GHS-compliant pictograms. Details include batch numbers, manufacturing dates, and recommendations for use within a defined shelf life. Users encounter clear instructions for gloves, goggles, and chemical-resistant coats, with no ambiguity about the risks. In my own lab experience, reinforced containers and absorbent liners are standard for shipping, reducing the odds of an accidental leak. Material safety data sheets get updated routinely, reflecting the steady flow of regulatory updates from REACH and OSHA.

Preparation Method

The most common route to acetyl bromide involves reacting acetic acid with phosphorus tribromide at room temperature. The cautious addition of phosphorus tribromide to glacial acetic acid, followed by purification through distillation, delivers the final liquid. This exothermic process doesn’t forgive sloppy technique; temperature spikes and product decomposition creep up fast without a water bath and careful control. On an industrial scale, engineers use continuous-feed equipment and inert gas blanketing to keep yields high, reacting to the sheer volatility and reactivity of every drop. Clean glassware, dry reagents, and attention to atmospheric moisture keep the risk and waste to a minimum.

Chemical Reactions & Modifications

Acetyl bromide makes short work of many transformations. Alcohols become esters, amines give amides, and carboxylic acids react to open doors to further derivatization. In a crowded synthetic route, acetyl bromide can replace acetyl chloride in delicate settings, especially if a chemist finds it easier to separate side-products from bromide intermediates. In the lab, students grasp the importance of adding acetyl bromide under dry, cool conditions to prevent runaway acid formation. Bromide’s reactivity offers unique advantages in modifying pharmaceuticals and polymers, where targeted acetylation matters for solubility or bioactivity. Some teams also experiment with mixed acyl bromides, chasing new reactivity for custom molecule production.

Synonyms & Product Names

Chemists often swap between names like ethanoyl bromide, bromoacetic acid, or acetyl bromide when referencing this reagent. Many catalogues list names with the same CAS number, including Ethanoic acid bromide or simply AcBr. Researchers working across borders check for these labels during regulatory registration or customs clearance, as the name on the drum or flask varies from supplier to supplier. Regardless of title, the risks and reactivity remain fixed; confusion in shipment or labeling can turn a safe delivery into a regulatory headache.

Safety & Operational Standards

Personal experience in the lab taught me that acetyl bromide comes with a strict protocol every time. Splashing a drop of the liquid or breathing in its acrid vapor can leave burns or trigger acute respiratory symptoms. Fume hoods act as the first barrier, but running water, spill kits, and neutralizing agents remain close at hand. Training drills cover every step, from bottle opening to waste disposal. Regulatory frameworks require dual-layer gloves, full face shields, and chemical aprons. Even then, accidents from hurried work often lead to expensive evacuations and costly lost time. Waste handling doesn’t end with reaction cleanup; neutralization, Segregated collection, and documentation extend the responsibility long after the reaction stops.

Application Area

Acetyl bromide steps into a wide range of fields, from laboratory research to bulk-scale chemical manufacturing. Pharmaceutical teams use the compound in acetylations to modify steroids, advance painkillers, and fine-tune drug delivery vehicles. Polymer engineers rely on it for tailoring the surface features of plastics and introducing functional groups that support adhesion or dyeing. In agricultural chemistry, acetyl bromide participates in the synthesis of herbicides and plant growth regulators, where purity impacts yield. It even finds a place in cellulose analysis; the compound breaks down lignin within biomass, letting researchers measure plant material composition to optimize feedstock or paper pulp. Each field demands not only chemical performance but precise handling, waste management routines, and ongoing training.

Research & Development

Recent years brought advances in acetyl bromide handling and reactivity. Chemists expand the toolkit through microwave-assisted acetylations or flow reactors that improve yield and safety. Academics dig into new acetylation methods, reducing solvent waste or swapping in greener reagents for supports or catalysts. Some groups test acetyl bromide in cross-coupling reactions, exploring routes to hybrid materials or drug scaffolds with fewer steps. Safety officers map out protocols for waste reduction and air monitoring, using real-time sensors to spot leaks before they cause harm. The ongoing push towards automation in synthetic labs brings fresh software and robotic handling to reduce human exposure to volatile acyl bromides.

Toxicity Research

Lab notes and literature reviews pile up on the hazards of acetyl bromide. Even brief exposure irritates skin and eyes, while lung contact with fumes quickly leads to coughing, chest tightness, or worse. Studies testing the effects on animal models reveal that breakdown to acetic and hydrobromic acids damages respiratory tissue and can inflame the gastrointestinal tract if swallowed. Regulatory bodies stepped in with clear exposure limits, emphasizing the need for one-way valves, sealed transfer systems, and prompt cleanup. Disposing of waste needs strong base quenching followed by careful dilution, making this reagent a costly option in labs with tight environmental controls. Despite these challenges, improved engineering controls and staff education remain the foundations of modern safe use.

Future Prospects

Looking ahead, acetyl bromide won’t go away. Synthetic chemists continue to seek out new acetylation strategies that cut costs or environmental impact but keep the reliable performance of classic acyl halides. Green chemistry trends push for on-demand generation, micro-scale use, or recycling systems to limit large-volume storage. The wider move to automated, remotely controlled labs promises fewer accidents and tighter exposure controls. Drug developers and packaging manufacturers keep tweaking acetyl bromide chemistry to support next-generation products, and new classes of biodegradable plastics or agrochemicals may depend on its unique reactivity. Ongoing partnerships between industry, academia, and regulators seek updated best practices—blending established core knowledge with fresh, real-world demands.

The Role of Acetyl Bromide in Labs and Industry

Acetyl bromide shows up in lots of conversations among research chemists, especially in university labs and production facilities focused on specialty chemicals. Its main use lies in slicing and dicing molecules—specifically, it helps attach an acetyl group to alcohols or phenols. This kind of reaction lets scientists build more complex molecules, or tweak natural ones to study their structure. it acts like a strong tool in the chemist’s kit, offering a route to substances that can’t easily get formed with milder alternatives.

In my own time working with organic synthesis, reaching for acetyl bromide always brought an edge of seriousness. The chemical reacts fast, so mistakes get noticed in a hurry. It demands respect—and careful handling—because that sharp, acrid smell tells you just how reactive it gets. This very reactivity makes it prized for tricky reactions where less aggressive chemicals fall short. In particular, it’s well-suited to transforming cellulose or lignin, letting researchers peek at plant matter in detail or prep samples for analysis.

Why People Don’t Walk Away From the Strong Stuff

There’s a reason some scientists put acetyl bromide above its cousin, acetyl chloride. Acetyl bromide can blast through certain barriers in tough molecules that stop other chemicals cold. One practical use: breaking down lignin in plant cell walls. Getting a clear answer about the content and structure of wood or biomass only works if everything gets dissolved and transformed without leaving anything behind. Paper manufacturers and biofuel labs lean on this route to get reliable numbers about their raw materials.

Drug makers chase purity. Sometimes a perfect result means testing new ways to add a small chemical group to a core structure without triggering unwanted leftovers. Acetyl bromide doesn't always win on safety, but it does get things done when standard reagents fail, especially for demanding research.

Health, Hazards, and a Path Forward

Workplaces adopting acetyl bromide make some real sacrifices for speed and power. Liquid fumes eat away at eyes and lungs, and just a few drops on the skin bring on strong burns. Safety lessons always repeat: suit up, use the fume hood, and double-check the spill kit is loaded. Health and safety teams stay alert, watching for irritation and coaching new colleagues through mock emergencies. Even as protocols improve, accidents happen when focus drifts or gear gets left off in a rush.

The path forward turns toward safer alternatives, greener methods, or at least tighter controls for ventilation and containment. Green chemistry programs, popping up in universities and major companies, push for reagents that break down cleanly or work without such harsh risks. New research explores catalysts and less toxic substitutes to do many of the same jobs—sometimes faster, frequently with much less environmental cost. Until those methods catch up for every reaction, acetyl bromide’s role stays secure.

Looking Beyond the Lab

Chemicals like acetyl bromide highlight the trade-off between getting things done quickly and working safely. Its story repeats in many parts of science and industry—pushing boundaries brings rewards, but also calls for hard choices and extra safeguards. Every batch of safer chemistry that replaces old habits matters, even if it starts with just a few careful hands in a single lab. Those choices build up, changing both the science and the future of how we treat our environment and each other.

Why Acetyl Bromide Deserves Respect in the Lab

Acetyl bromide doesn’t just smell harsh; it brings a real punch when safety slips. During my early days in the lab, I saw a seasoned chemist flinch from a simple whiff—he had worked with it so long that even a hint made him cautious. That was a warning worth carrying. This chemical grabs water from the air and reacts fast and aggressively. It breaks down to form hydrobromic acid and acetic acid, both of which eat away at tissue and corrode metal. My gloves came off ruined more than once, and the lesson stuck: proper protection isn’t just for the careless.

Personal Protective Gear: Always Essential

Forget latex—only thick nitrile or butyl rubber gloves stand a chance. Eyes demand wraparound goggles, and faces call for shields. Those faint chemical burns I nursed through a weekend proved that splash risk isn't a minor threat. A lab coat alone isn’t enough. Chemical aprons save clothes and skin, and closed shoes save toes from drips. I never reach for acetyl bromide without checking that all gear’s in place, especially after an accidental sleeve dip left a stubborn scar.

Ventilation: Real-World Lessons

Fume hoods do more than limit bad smells. Acetyl bromide’s fumes travel, and all it takes is a missed whiff to inflame lungs and eyes. I once tossed a small bottle into a regular trash bin and regretted it—corrosive vapors lingered long after. Working only in certified hoods, with airflow regularly tested, shields everyone’s breathing space. Even after finishing up, proper shutdown and checks stop lingering fumes from causing surprises after hours.

Storage that Keeps Trouble at Bay

This stuff doesn’t belong with water or alcohols. It sits best in sealed, glass-stoppered containers, away from any source of moisture. I found out early on why: a spill near a damp sink fizzed and stank so bad, the evacuation alarm rang. A dry, cool, locked cabinet, with acid-resistant trays underneath, sets a good standard. Clear labels warn off distracted hands, and spill kits never collect dust.

Emergency Response: Drills Save Skin

In a pinch, every second counts. I’ve watched confusion turn minor spills into emergency calls. Eye washes and safety showers work, but staff need real drills, not just signs on the wall. Every person in the lab knows where to run, and practice makes it routine. Spills should get handled with powder neutralizers, not heaps of paper towels. Fire extinguishers deserve regular checks, especially since acetyl bromide can ignite in some ugly ways.

Training and Mindfulness

Experience shapes respect. Every one of my labmates handles hazardous materials with the memory of close calls. Training sessions owe more to lived experience—precise, hands-on, and honest about screw-ups. Clear standard operating procedures get updated after every incident. Culture changes with honesty, and nobody should feel pressure to cut corners. Not once have I regretted taking a few extra minutes to check, double-check, and ask for a hand when working with acetyl bromide.

Building a Safer Future

Strong habits, solid gear, and honest conversation outdo any policy binder. Newcomers learn fastest by seeing day-to-day caution in action. Safety walks and feedback sessions don’t steal time—they build a lab where experience speaks and everyone goes home healthy. With chemicals like acetyl bromide, trust gets earned, and every shift starts and ends with respect for what can go wrong.

Understanding the Risks

Acetyl bromide isn’t your average chemical sitting quietly on the shelf. This liquid reacts sharply with water and moisture in the air. Fumes of hydrogen bromide and acetic acid come off almost as soon as the bottle opens. After witnessing a small spill once in a university lab, I haven’t forgotten the stinging in my nose or the panic that rippled across our team. Stories like this highlight the critical need for careful storage, since improper handling leads to injuries, chemical burns, and ruined experiments.

Picking the Right Container

Choosing the best type of bottle goes far beyond what might look sturdy. Acetyl bromide eats through many common plastics. Glass bottles with Teflon-lined screw caps give much better protection than standard plastic or rubber stoppers, which can corrode or leak. I’ve noticed that using containers clearly labeled with hazard warnings prompts less experienced lab members to handle them with the respect they deserve, which stops careless mistakes at the outset.

Controlling the Environment

Warm rooms and humidity ramp up the risk, since acetyl bromide reacts violently with any hint of water. Cool, dry spaces make all the difference. I recommend relying on a dedicated chemical storage fridge set well below room temperature. A desiccator cabinet, stocked with reliable desiccant packs, helps pull moisture out of the air and offers another layer of defense. Keep in mind that standard fridges with busy traffic aren't a good fit—one leaky cap or condensation issue can set off an accident.

Thinking Through Location

Placing acetyl bromide next to water sources or acids leads to trouble. Distance from sinks, humidifiers, and anything else prone to leaks shrinks the odds of an unwanted reaction. If shared laboratory spaces are a reality, opt for secure, separate storage away from frequently used chemicals. One mistake I saw resulted from a bottle sitting right beside a broken water bottle; since then, I store bottles on a high shelf within chemical safety cabinets built for volatile substances.

Personal and Team Responsibility

Labeling isn't busywork—tags noting the chemical's full name, concentration, hazard class, and date handed me peace of mind. Outdated chemicals or those past their expiration no longer belong in the lab. This sort of review creates a chance to teach new staff why the risks matter, not just how to tick the boxes. Proper training shows everyone how to check seals and recognize early signs of leaks or corrosion. Immediate reporting and swift clean-up become shared habits, not just checklist items.

Prepping for Emergencies

Accessible eyewash stations, fume hoods, and spill kits make the space safer. Reviewing spill procedures with every new batch of chemicals helps make reactions automatic, not panicked. I’ve seen well-drilled teams contain accidents much faster because they practiced beforehand, not just read the manual.

Staying Compliant and Up-to-Date

Respecting workplace safety rules and monitoring shifting chemical regulations offers real protection. Keeping Safety Data Sheets on hand, reviewing updated handling advice, and partnering with certified waste disposal outfits cuts long-term risk. Anyone storing acetyl bromide owes it to themselves and others to treat these guidelines not as red tape, but as life-preserving essentials.

Understanding What Hits the Bottles

Acetyl bromide is one of those chemicals you barely hear about unless you spend time in a lab or a chemical storeroom. Used for making acetates, researchers reach for this stuff when they’re breaking down complex plant material or tinkering with organic synthesis. The purity of what lands in a vial or arrives by courier can really set the tone for anything from a smooth research afternoon to a string of frustrating setbacks.

Common Published Purities

Most batches you’ll find sold by the big chemical suppliers land somewhere between 97% and 99% purity. That number isn’t pulled from thin air—it reflects just about the highest anyone can practically purify acetyl bromide before it becomes a pain in the neck or a danger to store. Impurities like acetic acid, hydrobromic acid, and moisture sneak in during production or handling, so perfection stays just out of reach.

Talking to chemists who order this stuff, anything below mid-to-high nineties sets off alarm bells. There’s an unspoken rule that nothing under 97% shows up in a research-grade bottle. Several of the industry’s stalwarts, such as Sigma-Aldrich, list 98% as their typical option—good enough for spectroscopy and analytical work. A few brands advertise “reagent grade” and “analytical grade” but, without specifics, nobody’s betting their research budget on anything that doesn’t pass a clear minimum.

Why Purity Matters in Real Life

Anyone who spent time running reactions knows how much a rogue impurity can throw things off. Water and acetic acid in these bottles lead to unpredictable yields or can mess up sensitive transformations. For example, a high school or college lab trying to demonstrate cellulose acetylation will see weaker, inconsistent results because side reactions or dilutions creep in if purity drops too low.

Industrial buyers with their own testing setups sometimes spring for “technical grade” acetyl bromide that lands closer to 95%. These are cheaper, but you never quite know what’s setting off an odd odor or strange discoloration until you run quality checks. For most folks who need to work by the book or publish results, hitting that 98% mark is the least stressful path.

Keeping Quality Reliable

Quality doesn’t stick around just because the supplier says so. Acetyl bromide pulls in moisture like a sponge—storing an open bottle for a few days can kill the numbers on your certificate of analysis. I learned that the hard way as a graduate student: a bottle that shivered open in humid air led to a ruined column and a week wasted repeating reactions. These chemicals demand airtight bottles and, sometimes, needing to work fast or split purchases among different cold rooms.

Promising Solutions for the Market

There’s been a push for clearer labeling and documentation in the chemical supply chain. Pre-packaged ampoules and single-use breakable vials have shown up to tackle the moisture problem and stamp out casual contamination. The industry also leans more on batch certification and “just-in-time” shipping, with most reputable suppliers furnishing certificates of analysis detailing every impurity above a small threshold.

It’s easy to overlook these details until a project, experiment, or process starts failing for reasons nobody can explain. For the student or professional, asking a supplier for recent batch data, buying only what’s needed, and sealing bottles tightly pays off more than counting on luck or trust. The small habits—taking time to note how clear the color is, sniffing for sharp residual odors, staying picky about purity—make the biggest difference in the longevity and outcome of any work involving this strong but sensitive chemical.

Digging Into Daily Storage Realities

Acetyl bromide doesn’t stick around forever. It shows up in labs for a reason: it’s a sharp, useful reagent for making esters and playing around with cellulose. Anyone who’s worked with it gets this spicy, vinegary smell, hinting at both power and liability. More than most chemicals on the shelf, acetyl bromide wants to react—especially with water vapor. That means trusting the label for a “best by” date can get risky if someone cracks the bottle too often or the storage isn’t up to par.

Reactivity Cuts Time Short

Manufacturers usually recommend using sealed acetyl bromide within a year. Open it even once, and the clock races. Humid air eats away at its purity, turning some of your reagent into acetic acid and hydrobromic acid. That transformation isn’t just a pain for yields; it can spell trouble for safety and data integrity. A shelf full of compromised acetyl bromide throws a wrench in the works. It feels wasteful, but tossing a suspicious bottle costs less than cleaning up corroded storage or contaminated syntheses downstream.

The Test: Trust but Verify

Relying on paperwork and dates doesn’t match up to what happens in flasks. Labs with a habit of spot-checking their chemicals—and actually recording those results—not only save money in the long run but dodge big trouble. Thin-layer chromatography or NMR analysis can flag decomposition early. Sure, not everyone wants to divert time from the real project, but every failed reaction due to rotten acetyl bromide proves the value.

Handling and Storage Make the Difference

Even before anyone thinks about the shelf life, storage practice sets the baseline. Acetyl bromide stays in dark glass, under dry argon or nitrogen, in a cool spot. Air and light creep in quickly if someone leaves it out mid-experiment. Training new chemists on these habits means fewer ruined bottles and safer labs. No storage trick can stretch acetyl bromide's life indefinitely, but careful practice keeps most losses at bay.

Regulations and Safety Shouldn’t Be Afterthoughts

It’s easy to get caught up in the daily grind, but ignoring safety around acetyl bromide can end careers as quickly as a phone call from the EH&S office. Local rules often force regular checks and dated inventories. That’s not bureaucracy for its own sake—old acetyl bromide lets off fumes that corrode containers. Catching that on an inventory walk-through beats a midnight alarm any day. It’s part of responsible stewardship to track, test, and swap out old stock before it becomes a bigger risk.

Making It Work: Practical Solutions

To stretch the value of each purchase, labs can buy just what they need for the immediate future. Smaller aliquots mean less time for each bottle to go stale. Real records—written, not just remembered—build a culture of responsibility. Sharing stories of botched experiments due to degraded chemicals helps newcomers learn that shortcuts on storage or use hurt everyone. Simple steps like these let labs pull more useful chemistry from every drop of acetyl bromide, with fewer headaches down the line.